In the high-stakes world of modern mining, the line between a profitable venture and a missed opportunity is thinner than ever. As high-grade ore deposits become harder to find, the industry is turning its attention to lower-grade materials and the vast potential of tailings reclamation. In this environment, the laboratory is no longer just a support service; it is the engine room of economic viability. When you are quantifying trace metals at ultra-low levels, even a microscopic speck of environmental dust can skew your data, potentially leading to false positives or masking the true value of a mineral deposit.

If you’ve ever sat in front of your workstation wondering why your Blank and Background Equivalent Concentration (BEC) values are stubbornly high, you aren’t alone. It is a common frustration for geochemical analysts: your instrument is calibrated, your reagents are fresh, yet the background noise refuses to quieten down. These elevated values aren’t just technical nuisances; they directly impair your Limit of Quantification (LOQ). In a world where a $0.1\text{ g/t}$ difference in a gold tailings project can determine financial success, “noisy” data is a risk you cannot afford to take.

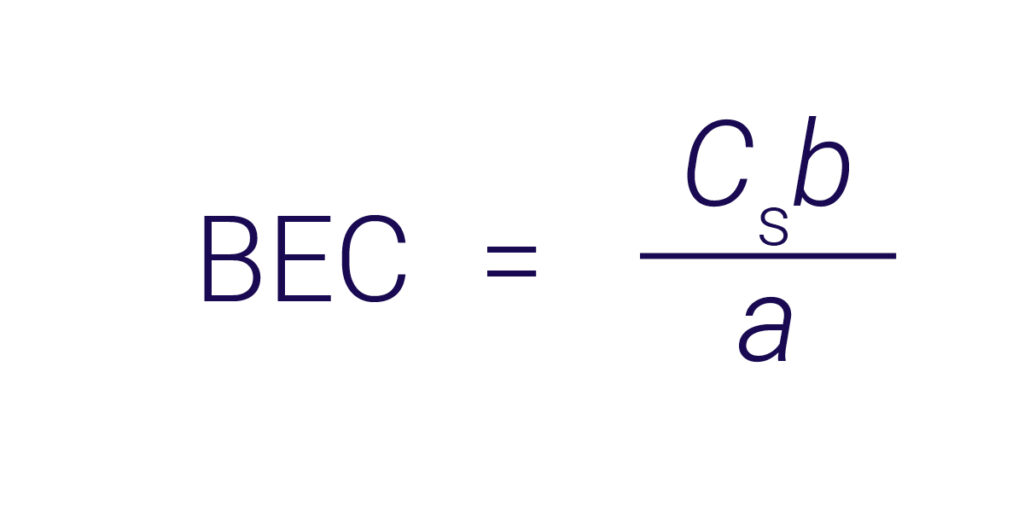

To solve the problem, we first have to understand it. The BEC represents the total background signal of your analytical system – essentially the “noise” the instrument sees when no sample is present. When this noise is high, your instrument struggles to distinguish a genuine analyte signal from the background. This directly pushes up your LOQ, making it impossible to accurately quantify the lower concentrations that modern mining exploration demands. The root cause of these high values? It usually comes down to one single, persistent word: CONTAMINATION.

If your sample preparation isn’t meticulous, even the most advanced mass spectrometer will produce compromised results. Contamination is a silent thief that enters your workflow through water purity, reagent quality, and even the laboratory personnel themselves – common culprits include cosmetics, jewellery, and the powder in traditional gloves.

The Chemetrix Edge: We don’t just supply tools; we build expertise. Through the Chemetrix Lab Advisor, we provide your team with the specialised skills needed to identify and eliminate these “time traps”. By pairing this training with high-purity Inorganic Ventures Certified Reference Materials (CRMs), you ensure your calibration is built on a foundation of absolute purity.

While a clean bench is vital, the right hardware can act as your final line of defence against complex mineral matrices. Mining ores are notorious for their high levels of dissolved solids, which traditionally require extensive manual dilution – a process that introduces even more opportunities for human error and contamination.

The Chemetrix Edge: We recommend the Agilent 7850 / 7900 / 8900 ICP-MS series as the physical solution to these high-matrix challenges. These instruments are equipped with Ultra High Matrix Introduction (UHMI) technology, which uses clean Argon gas to “dilute” your sample aerosol before it even reaches the plasma.

By using the Agilent 7850’s UHMI system, your lab can directly analyse samples containing up to $25\%$ total dissolved solids without manual liquid dilution. This not only saves hours of labour but practically eliminates the risk of dilution errors and reagent-born contamination.

The ultimate goal of refining your workflow is simple: lower LOQs and higher confidence. When you master your contamination control, you unlock the ability to see value where others see waste. Successful tailings reclamation depends on this precision. By accurately monitoring recovery at trace levels, mining operations can turn legacy liabilities into profitable resources, contributing to a more sustainable and circular mining economy.

Ready to lower your detection limits and boost your lab’s productivity? It starts with a partnership that understands your specific challenges.

Review your prep: Identify one source of potential contamination today (check those gloves!)

Audit your standards: Ensure your CRMs are matrix-matched to your ores for better accuracy.

Connect with Chemetrix: Let our team of scientists help you tailor a solution that combines Agilent’s world-class technology with practical, on-the-ground support.

Let’s advance science together. Contact Chemetrix today to explore how we can elevate your laboratory’s performance.