When regulatory limits for toxic elements in food keep getting stricter, labs face an uncomfortable reality: the methods they’ve relied on for years might not be fast enough or sensitive enough anymore. Analysis times stretching beyond 10 minutes per sample create bottlenecks. Coupling different instruments feels risky. And when your lab is responsible for detecting inorganic arsenic in baby food or cadmium in rice, there’s no room for error.

Here’s what most food testing labs don’t realise: the perceived complexity of coupling HPLC to ICP-MS is largely a myth. With the right hardware and software integration, what seems like a daunting technical challenge becomes a routine workflow that delivers results in under two minutes per sample.

Walk into any food testing laboratory and you’ll hear the same concerns. Analysts are under pressure to process more samples with the same resources. Method development feels like reinventing the wheel for every new matrix. And when regulatory bodies lower action levels for toxic elements, labs scramble to validate new methods while maintaining daily sample throughput.

The real frustration? Many analysts believe that analysing inorganic arsenic, cadmium, lead and mercury requires complicated instrument coupling that only specialists can handle. They’ve heard that HPLC-ICP-MS is temperamental. They worry about stability over long sequences. They’re concerned that different vendors’ systems won’t communicate properly.These concerns create dangerous hesitation. Labs stick with older, slower methods because they’re familiar, even when those methods can’t meet new regulatory requirements. Sample backlogs grow. Turnaround times stretch.

The bottleneck isn’t the science. It’s the assumption that the solution has to be complicated.

Not all arsenic is created equal. Total arsenic measurements tell you how much is present, but they don’t tell you the critical part: is it toxic? Inorganic arsenic (the sum of arsenite As(III) and arsenate As(V)) is significantly more toxic than organic arsenic compounds like arsenobetaine found naturally in seafood. This is why regulations specify limits for inorganic arsenic rather than total arsenic. A rice cereal might contain arsenic, but if it’s all organic forms, the health risk is minimal. If it’s inorganic arsenic, even at low concentrations, it poses a developmental risk

to infants.

The same principle applies to other toxic elements. Cadmium accumulates in rice grown in contaminated soil. Lead and mercury, even at trace levels, affect neurological development in children. The US House of Representatives report in February 2021 found that many baby foods sold in supermarkets contained unacceptably high concentrations of these elements.

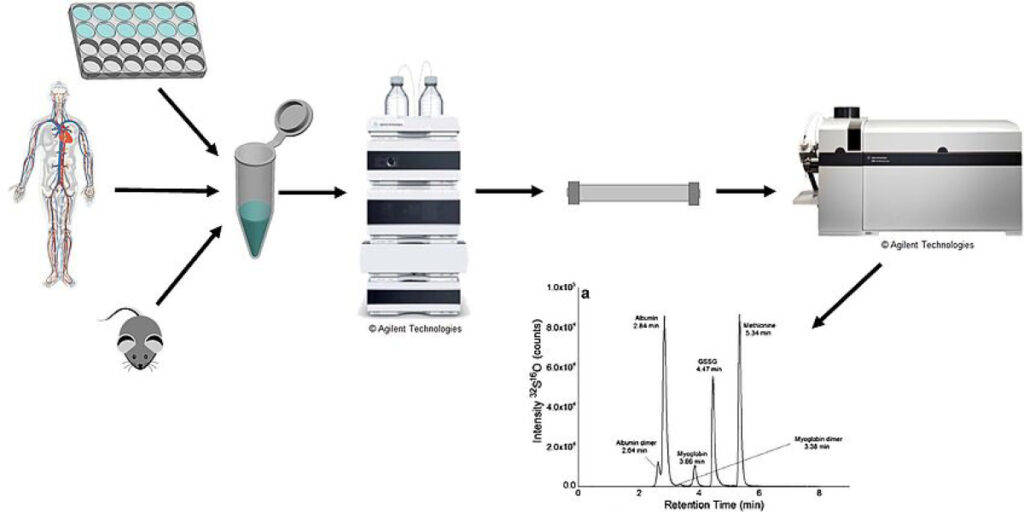

This is where speciation analysis becomes critical. HPLC separates different chemical forms of arsenic before ICP-MS detects them. By oxidising As(III) to As(V) during sample preparation, the analysis simplifies to measuring one peak representing total inorganic arsenic. The chromatographic separation happens in under two minutes, the ICP-MS provides sensitivity down to parts per billion and labs can confidently determine whether a food product meets regulatory limits.Food testing labs aren’t just generating data. They’re protecting the most vulnerable consumers: babies, infants and young children whose developing bodies are most susceptible to toxic element exposure.

Image credit: Institut für Analytische Chemie Universität Wien

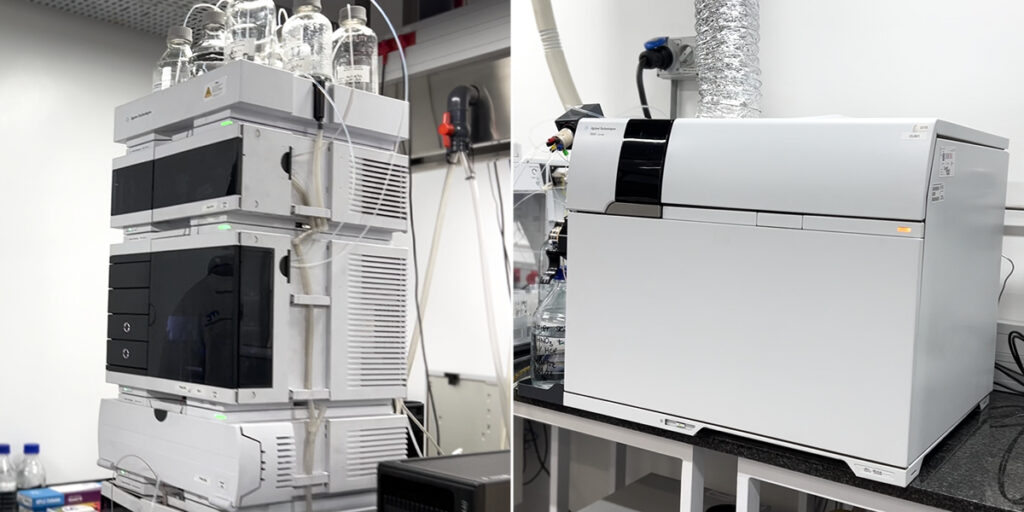

The breakthrough isn’t in the HPLC or the ICP-MS individually. Both instruments are well known in the industry for performance and robustness. The efficiency gain comes from how they work together. Agilent developed an optimised interface that physically couples the Agilent 1260 Inifinity III HPLC to both the 8900 ICP-QQQ and 7850 ICP-MS systems. But the real innovation is software integration. The entire coupled system is set up and operated from the ICP-MS MassHunter software. One interface. One method. Automated analysis.

Single software control means analysts don’t toggle between platforms or manually synchronise instrument parameters. Method development happens in one place.

Stable hardware coupling removes the guesswork from connecting instruments. The optimised interface ensures consistent sample transfer without leaks, dead volume or carryover issues.

Reduced setup time transforms HPLC-ICP-MS from a specialist technique into a routine capability. Labs new to speciation analysis can implement the method without extensive troubleshooting.

Fast 2-minute runs change the economics of compliance testing. When analysing inorganic arsenic requires 10+ minutes per sample using conventional columns, labs face real capacity constraints. At 2 minutes per sample, the same instrument processes five times the volume.

The 7850 ICP-MS adds practical features that matter for real-world food matrices. Ultra High Matrix Introduction (UHMI) handles samples with high dissolved solids without constant maintenance. The IntelliQuant function provides instant visibility into total matrix composition. And helium collision mode addresses spectral interferences without complex method optimisation.

The US Baby Food Safety Act 2021 proposes maximum levels of 10-15 ppb inorganic arsenic depending on whether products are cereal-based. The FDA’s Closer to Zero plan phases in action levels for lead, arsenic, cadmium and mercury through 2024 and beyond. EU regulations specify limits for inorganic arsenic in rice between 0.1-0.3 mg/kg.

These aren’t aspirational targets. They’re enforceable limits that require labs to deliver accurate, defensible results.

The Agilent 1260 HPLC coupled to the Agilent 8900 ICP-QQQ provides the sensitivity and speed food testing labs need. The 8900 offers detection limits of 1.99 µg/kg for solid samples and 0.08 µg/L for liquid samples, well below regulatory action levels. The method complies with FDA Elemental Analysis Manual sections 4.7 and 4.11, as well as European standards EN16802:2016 and prEN17374:2019.

Real-world validation across baby foods, rice cereals, beverages and animal feed demonstrates recoveries between 82-111% with precision from 0.3-9.4% RSD.

📚 LEARN MORE: Application Note: Analysis of Inorganic Arsenic, Cadmium, Lead and Mercury in Baby Foods by ICP-MS (5994-3713EN)

Agilent 1260 Infinity III LC System

Food manufacturers testing ingredients before use or finished products before release face a different challenge. They need screening capability that keeps pace with production schedules. Samples can’t wait days for results. Backlogs mean inventory sitting in quarantine.

The Agilent 1260 HPLC coupled to the Agilent 7850 ICP-MS delivers the throughput production labs require. The 7850 combines proven hardware with software features that simplify workflow for analysts who may be new to ICP-MS or new to Agilent systems. The 7850’s 10 orders of magnitude linear dynamic range means major and trace analytes are measured in a single run. No over-range failures. No sample reruns. The system processes samples with per cent-level total dissolved solids thanks to UHMI technology as standard.

For inorganic arsenic screening in rice cereals, the fast HPLC-ICP-MS method reduces analysis time from over 10 minutes to under 2 minutes. The short anion exchange column, optimised mobile phase and small injection volumes maintain baseline separation of inorganic arsenic from organic species without compromising resolution.

There’s a pervasive mindset in many labs that complexity is just part of the job. That coupling instruments will always be difficult. That fast methods sacrifice accuracy. That meeting new regulatory limits requires hiring specialists or sending samples to reference labs.

Chemetrix rejects this narrative. Labs shouldn’t have to choose between speed and accuracy. They shouldn’t accept that advanced techniques are only accessible to experts. And they absolutely shouldn’t operate under the assumption that their current capabilities define their future possibilities.

This is where partnership matters. Chemetrix doesn’t just supply instruments. We advocate for a scientific culture grounded in integrity, accuracy and respect for the people doing the work. When we say the Agilent HPLC-ICP-MS coupling is easier than labs think, we’re not minimising the science. We’re affirming that with the right tools and support, routine labs can deliver extraordinary results.

The optimised interface, integrated software control and proven application methods aren’t just technical specifications. They’re a commitment to removing barriers between labs and the capabilities they need.

Toxic element analysis in food doesn’t have to be the bottleneck in your lab. The perceived complexity of HPLC-ICP-MS coupling dissolves when hardware and software are designed to work together from the start.

Download the application notes for baby food and rice cereal analysis to see validated methods and real-world results. Contact Chemetrix to discuss how fast HPLC-ICP-MS screening can eliminate testing bottlenecks in your facility.

Food safety depends on labs that can deliver accurate results quickly. With the right partnership and the right tools, your lab can be exactly that kind of asset.